How The PRO-SERIES Airflow Generates More Power

As with anything, carburetor sizing is a compromise. The name of the game is creating the best-case blended scenario of mass air flow and velocity to achieve the least number of drawbacks. To better explain this relationship, let’s visualize the dynamics of a river. Air flow is the total volume amount of water the river is flowing, and velocity is the speed at which the water is traveling. In areas where the river becomes narrower, the water will speed up because the flow rate is constant for the same water level. If you add water to the river through a rainstorm, and the water level rises, the flow rate will increase. In essence, you can increase the velocity of the river by pushing the same volume of water through a narrower channel, by adding more water and increasing the total volume to the same size river, or both. However you cannot increase the flow of the river without having more water to flow through it.

This analogy carries over nicely to carbs. Now imagine we have built a dam on the river (throttle slide) and on the other side is a lake (cylinder). Our goal is to fill the lake with as much water as possible within a specific time range. With motors, as the throttle position progresses, it will pull more air but this example, throttle position will be represented by the opening size of the dam and the allowed water. I.e; 25% throttle = 25% opening of the dam. The engine size (CC’s) will determine the maximum amount of air it is able to consume. In this example, the bike’s engine size will predetermine the volume of water we can add in our river with each RPM. Now, imagine a bigger carburetor for your engine. Bigger carb = bigger riverbed but the flow increase will be negligible because the volume of your engine cant create enough pressure to pull more air. As you increase in RPM, you add more air, and the flow rate will increase. This is where the compromise takes place.

Velocity is important for several reasons. The first of which is it’s one of the driving forces that pulls fuel from the bowl of the carb. As velocity increases in a carb, pressure decreases, which creates the suction that pulls fuel into the engine. Additionally increased velocity creates more of a shear force that breaks up fuel droplets into different sized particles. By inserting fuel into different points of the flow stream, not only are you able to control your fuel delivery, but you are also able to control your fuel particle size distribution. The benefits of this can especially be seen in our PRO-SERIES. With conventional carb bore designs there is a tradeoff between flow and velocity, and OEM carb sizing reflects this. 125cc bikes for motocross are using 38mm carbs while 300cc enduro bikes are using 36mm carbs due to the demands of the disciplines they’re being used in. 125cc Motocross bikes spend a lot of time at high RPM where flow is important, and 300cc Enduro bikes spend a lot of time at low RPM where velocity is important. This tradeoff comes from the fact that more velocity makes more friction which slows down flow.

Our PRO-SERIES bore design has found a unique solution, so you don’t have to compromise: Make a carb that flows more than a 38 while having more velocity than a 36. But how is this possible? Traditionally, carb bores have been compared, tested, and often selected from a flow bench result. A flow bench is a device that pulls vacuum on one side of an object at a set amount of pressure, then measures the flow that the object lets through. While flow benches can be very useful, they are often utilized or analyzed incorrectly. In the bike world, flow bench testing is done at 10in-H20, and in the automotive world it is done at 28in-H2O. With typical flow bench testing, the part being tested is isolated to its individual capabilities and not to its contribution to the applicable vehicle’s engine. Understanding a specific part’s maximum CFM is important, but understanding how it correlates with your engines capabilities is critical. For example, the PWK38 has a max of 143CFM at 10in-H20, but a 250cc dirt bike at 100% volumetric efficiency only has the capacity to pull 88CFM

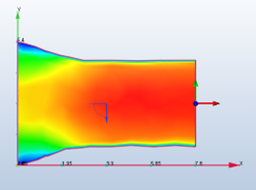

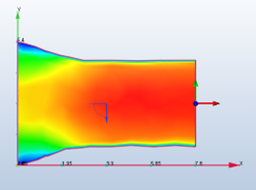

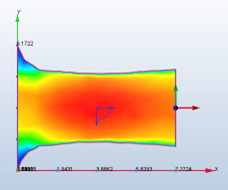

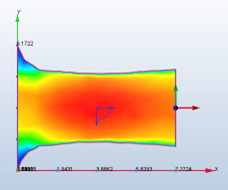

We combined years of flow bench data with drag racing velocity stacks and Computational Fluid Dynamics (CFD) to engineer a bore design that increases velocity without decreasing flow. This results in our customers not having to compromise.

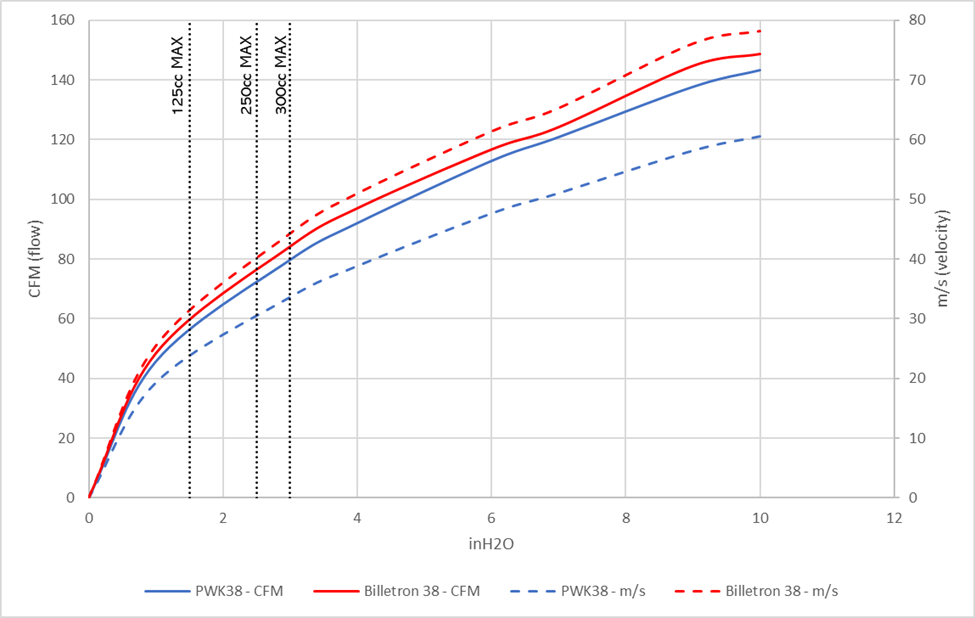

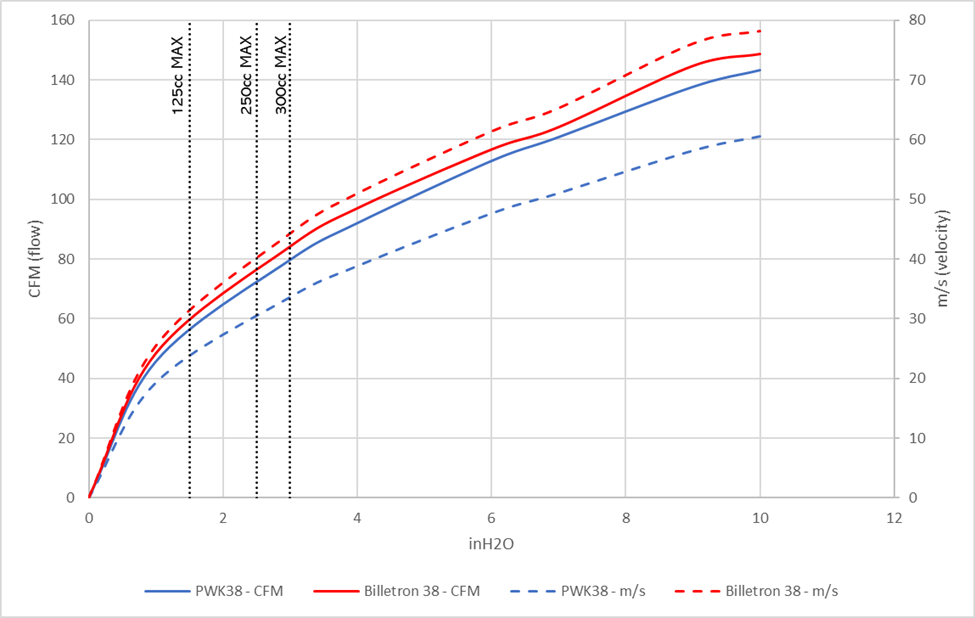

Above you can see a plot of CFM (flow) and m/s (velocity) for a PWK38 and our PRO-SERIES 38. The vertical dotted lines are the max vacuum numbers for an average bike of each displacement. These numbers were determined by CFD analysis and then backed up by real world flow bench and dyno testing. Notice how none of those bikes get close to 10in-H2O;

Analyzing only flow bench without consideration of engine volumetric capabilities, the Billetron bore design can expect a 4% gain in flow (helping with peak power). However, taking into consideration engine volumetric capabilities, there is a 6% gain in flow in the usable range of the graph, with a staggering 32% gain in velocity, which results in massive power gains across the board.

For bikes in the 125cc to 250cc range, we’ve found that the velocity vs flow characteristics of our 38 bore design are optimal for most applications. For over 300cc, we designed a larger bore carburetor called the “Big Air” that focuses on flow more than velocity. There is no advantage to using our Big Air Carbs (vs our 38 carbs) on 125-250cc bikes unless they are highly modified for more very high RPM use (Road race, Karting, etc). Bikes that are right at 300cc are able to benefit from either our 38 or Big Air models, depending on the characteristics of that specific bike, and what they’re being used for. A good rule of thumb is to use the 38 for more enduro or mixed use, and the Big Air for motocross or desert style riding. For more info on sizing a carb for your specific bike, feel free to reach out to our Tech Team!

Learn how our PRO-SERIES delivers fuel to match this air flow